With all our talk about how awesome radial piston engines are when used to power miniature brush cutter attachments, we thought we should answer your next question… How do piston engines work? radials?

key points

- A radial piston engine has pistons arranged in a star shape around the output shaft.

- At the end of each piston is a roller that allows the piston to travel around an eccentric cam ring.

- Hydraulic pressure pushes the piston against the eccentric cam ring, the cam ring lobes push the piston back, causing the rotational force.

What is a radial piston engine?

As an introduction, radial piston motors are a type of hydraulic motor commonly used to power machinery such as forklifts, skid steers, and excavators. Often used as a “direct drive” motor, it requires no reduction gears and can be bolted directly to travel components.

The fact that it is used in conditions that require great power is no accident. By design, radial piston motors provide high torque, low speed, smooth operation, and have a longer service life than other common hydraulic motors when properly used and maintained.

How does a radial piston engine work?

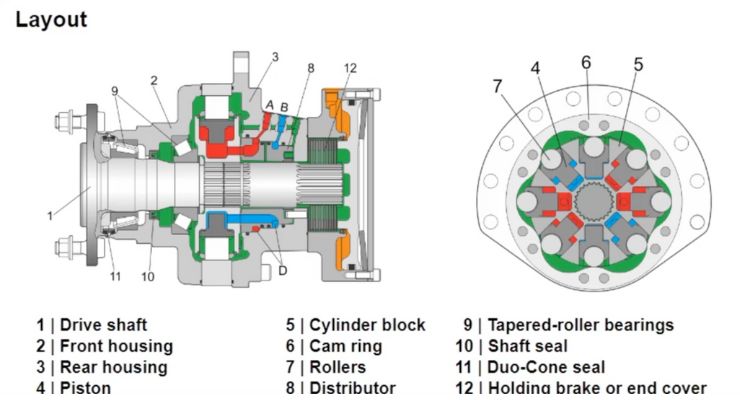

There are two main components to understand when discussing how a radial piston engine works. One is the eccentric cam ring and the other is the pistons themselves.

Eccentric cam ring

An eccentric cam ring is an internally fixed ring around the inside of the engine housing that the pistons push against to provide torque and rotation to the output shaft.

The trick to radial piston engine operation is the fact that the cam ring is “eccentric”. This means that instead of the ring having a uniform shape, it has built-in lobes and valleys. This is an important consideration as we will discuss later.

Radial pistons

As the name suggests, a radial piston engine has pistons arranged in a “ray” around the output shaft. You can also think of these pistons as being arranged in a star formation, with one end attached to the output shaft and the other end in contact with the eccentric cam ring.

At the end of the piston is a “roller” that allows the piston to travel along the cam ring, which as you will see is key to the operation of radial piston engines.

How do they work together?

Pressurized hydraulic oil is sent from the miniature to the brush cutters radial piston engine. Oil is used to pressurize the pistons as they travel through the cam ring lobes. The piston, with its roller pushing against the cam lobe is what creates the rotational force.

When the piston reaches the bottom of the valley in the cam ring, it will no longer receive pressurized oil. As the piston is pushed back into the next cam lobe, it will return the oil inside its cylinder to the return line.

Once the piston moves back down the next cam lobe, it will again receive pressurized oil and press on the cam ring to add more rotational force. Ultimately, every time a piston rolls through a cam lobe, it is pushing and providing rotational torque.

Like other types of piston engines, a radial piston engine will have more than one piston applying power at the same time. This ensures that continuous power is applied throughout the entire rotation of the drive shaft.

Watch this video below from the “Rotary Power” Youtube channel to see a video of it in action.

Other Brushcutter Engine Components

Your brushcutter’s radial piston engine will be accompanied by a distributor and manifold block that regulates and controls the hydraulic fluid pressure entering and leaving the hydraulic motor.

Brushcutters with radial piston engines often require a case drain line. This relieves excess hydraulic pressure from the engine and is vitally important.

If your miniature brushcutter’s engine requires a case drain line, even operating the brushcutter momentarily without the case drain will undoubtedly damage the engine and void your warranty. Consult manufacturers recommendations.

As with any hydraulic motor, there will be several sets of bearings to allow the moving parts to rotate freely. Seals on both ends of the motor are used to keep lubrication in the motor and dust and dirt out.

Radial piston brush engines – Other considerations

It is vitally important to keep the hydraulic fluid clean when using any radial piston engine. The pistons inside the engine are manufactured to tight tolerances and any amount of dirt or debris will quickly mold the engine.

Brush cutters, in particular, tend to throw dust, dirt and debris in all directions. A good practice is to make sure the hydraulic couplers are perfectly clean before connecting or disconnecting them to the miniature.

Common radial piston engine specifications

-

Radial piston engines are commonly built with displacements from 150cc to 3000cc, but when used in miniature brush cutter applications, 150cc to 250cc is common.

-

Radial piston engines are typically designed for a maximum of 100 to 900 revolutions per minute. When used with a brush cutter, the RPM will be at the lower end of this range.

conclusion

Radial piston engines are the perfect way to power your miniature brush cutter. With its simple direct drive, low speed and high torque capabilities, it is an obvious choice for heavy duty brush cutters.

If you would like to discuss more about how these motors work, or any other miniature hydraulic motors, please feel free to contact the author directly via the links provided.