Unearthing insights to improve a construction schedule and solve problems before they happen is no small task, but a new AI-based tool from ALICE Technologies is able to optimize schedules directly from an Oracle file Spring P6.

In construction planning, keeping track of the countless variables at work on complex projects can make the process seem more like an art than a science. ALICE’s original goal when it first introduced its AI-based schedule optimizer in 2017 was to find a better path through this project delivery wilderness.

This system used element-based analysis of construction schedules to account for every piece of a project’s building information model and what would be needed to build it, down to work crews, deliverables of material and access to the necessary site. The algorithms underlying the system work from a series of “recipes” of what is needed to build various building elements: floors, columns, etc. The system then simulates the construction of the building from the BIM data, taking into account what is required. to complete the various tasks and how they should be sequenced.

This initial version of ALICE has come a long way in the intervening years and has been used on hundreds of projects, from vertical construction to large and complex oil and gas installations. But despite the scheduling advantages ALICE offers, it has so far been limited by the requirement for a detailed BIM to ingest, says Rene Morkos, founder of ALICE.

“We went back to the drawing board,” he says. “Customers loved our product, they took a BIM and ran simulations, but they always asked, ‘Can you do this from a P6 program?'”

Because the ALICE system has improved from the many projects it’s been used on, Morkos says they’re confident it can work right off the schedule. The existing ALICE product derived from BIM will become ALICE Pro, while the new product derived from P6 will be known as ALICE Core.

“For the first time, we’re speaking the same language that programmers and GCs use,” says Morkos.

The company has partnered with Oracle to ensure the Primavera P6 import/export process is relatively smooth, and Morkos hopes this new approach will bring the benefits of an AI schedule optimizer to users who weren’t interested in creating complete BIMs for their projects. .

“The aspiration is to bring this construction option to a much wider audience, which is no longer dependent on BIM,” explains Phil Carpenter, Marketing Director of ALICE. He adds that in addition to opening it up to U.S. clients who have been slow to move to BIM-based project delivery, it also allows ALICE to bring improvements to smaller projects that typically don’t warrant creating highly detailed BIMs. .

The process for using ALICE Core basically has two steps. First there is the evaluation phase, where the system digests the P6 XCR file and presents it in a consistent sequence with all variables labeled and linked. Labor, materials and other factors are extrapolated from P6 and presented in a visual representation of the schedule. The process only takes a few minutes and allows planners to examine their project in its entirety, with all dependencies and variables represented by arrows and tick marks.

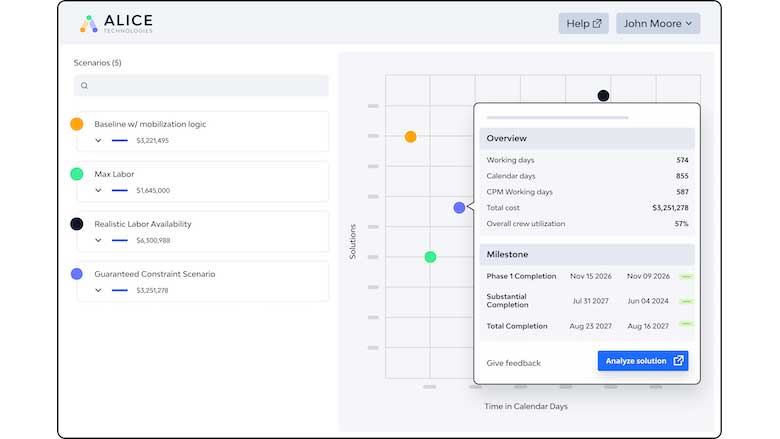

The next step, which takes a bit more time for the AI-based system to run, is the recovery phase, where the ALICE system re-sequences and shuffles the tasks and other scheduling elements to see if it can save time, money or meet. other user-defined restrictions. This may involve the user tinkering with small changes to see how they would affect the cost or time of the project, or simply setting fixed cost, time, labor, or equipment constraints and sitting back while ALICE rearranges everything to meet those requirements.

“The thing about ALICE is that it will never allow you to produce a schedule that violates the constraints you set,” says Shane Richardson, president of LaGrange Consulting, which advises large project owners and general contractors on their cost and schedule issues. “And anyone can do this with ALICE, do it and see the problems in the project.” Richardson says that just the initial step of visualizing the P6 schedule has been helpful for several of his clients working on large industrial projects.

Richardson says the ability to set such specific constraints as site conditions, regulatory goals, project-specific milestones, equipment availability, crew size and other factors allows a new user to begin fine-tuning the project schedule significantly after just a few minutes of training.

“ALICE is quite a different way of programming, but I think it’s the future way of doing things – they’re way ahead of the curve, and it’s hard for companies to get fully into ALICE,” says Richardson. “This new integration with P6 is the step to import your programming and see potential improvements right away.”

Any file generated in ALICE Core can be re-exported to Primavera P6, allowing planners to work again with their new optimized workflow, says Carpenter. “It really helps democratize what we’ve done previously,” he says.

Morkos adds that his team enjoyed getting their sophisticated AI-based system to a point where anyone running a project can enjoy its benefits. “We had previously built an F-16 [fighter jet]but now we’ve built a Ford F-150 with an F-16 engine.”